.

VENEER SHEETS

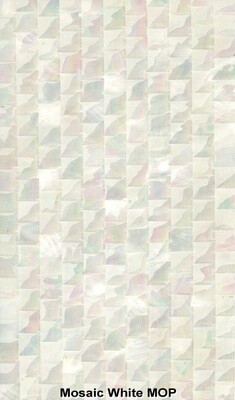

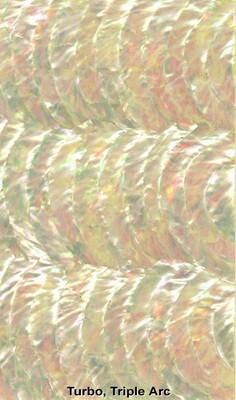

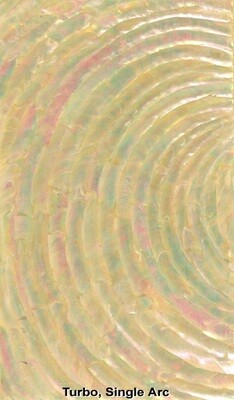

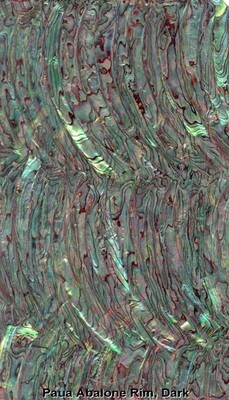

5½" x 9½" (140 x 240 mm), and sold individually. Listed thicknesses are nominal, but even, as some types of shell can be worked thinner than others without breaking apart during manufacture. Colors are well matched, edges are trimmed, some sheets may have slight corner chipping or contain areas of slight “worminess”; there will be color variations between sheets or batches.

This amazing product has found important uses in manufacturing applications where large areas need to be covered, or costs lowered, while keeping or improving existing quality. These materials are very thinly-sawn pieces of shell (.006" to .013" thick), painstakingly assembled into large sheets composed of matched-color pieces overlapped and glued together, then sanded flat on both sides.

Moderately flexible, they can be used to cover or cap banjo pots and resonators, as well as pegheads, heel-caps, pickguards, truss-rod cover plates, solid-body guitar tops, drum barrels, furniture, fishing lures, surfboards/skateboards/snowboards, box tops and sides, nameplates, and many other items. “Artistic” sign makers and automotive pin stripers are using these in combination with gold leaf and other techniques to fill or outline ornate lettering or designs, often behind glass (“reverse glass” work). Shell decals would even be a possibility!

Very delicate, trimming can be done on simple shapes using a single-edged razor blade or even a very sharp scissors.Veneers can be temporarily glued to a thin backing material, cut with a saw, then released by soaking in water or other solvent (soaking is not recommended for the composite sheets without testing first).For cutting intricate shapes, several methods have been used: computer cutting of glued-down veneers; cutting a glued stack of veneers which are later separated; and masking and sandblasting.

For sandblasting, the veneer is glued to a piece of scrap window-glass (available free at any glass shop) using “textile table adhesive”, covered with vinyl mask (frisket paper), the pattern drawn or transferred onto the frisket, and the frisket cut along the pattern lines with a knife or razor (or computer-cut frisket patterns can be used), the background paper removed “weeded out”), and the shell blasted with a very fine sand until glass is reached. Use a citrus-based glue/label remover to release the veneer from the glass, then soak about one hour in water to remove the frisket from the veneer. Any sign shop supply carries both the vinyl frisket and the table adhesive (used to hold fabrics in place while being silk-screened).

Veneers can also be painted or silkscreened with a design, which leaves exposed the areas to be seen as shell, then protected with a clear finish. We can supply advice on any of these methods.

Many of the veneers will show deepest colors if used over a black substrate, but overall tone can be greatly influenced by the use of different colored backgrounds, painting color on the backside, or sizing and leafing the backside with gold, silver, aluminum, Dutch metal, copper, etc. Thicker foil materials can also be used to back veneers with.

The thinnest veneers are not suitable for actually “inlaying”, but are intended for “overlay” work, and are thin enough that lacquer or enamel finishes can be built up flush with the shell and then buffed down level. The thicker sheet material (.010” - .013”) is sometimes employed as actual inlay, but this is usually done using computer-operated machines which can control the routing depth within .001”. Sometimes both the veneer and it’s backing material are inlaid as one piece, to make handling easier. This is less common now that our LAMINATED ABALAM® SHEETS are available.

To make guitar pickguards, the veneer sheet is shaped, then run through a plastic laminator (as used in many instant copy shops), the plastic trimmed to leave a slight overhang, and a double-stick adhesive applied to the backside so it can be mounted on the instrument.

To cover plastic tuning knobs on instruments, thin veneer is super-glued to both faces of the knob, the edges dressed off, and the perimeter of the knob wrapped with shell and dressed off. To keep the veneers from breaking apart when forced onto a curved shape, it helps to cover one surface of the shell with heavy clear packaging tape, which is removed once the veneer is glued to the knob. This is a trick developed by the Custom Shop at Fender Instruments.

Buy Shell Inlays & Sheets from the Duke of Pearl – Since 1967 we’ve been the world’s best source for top quality mother-of-pearl (“MOP”) and abalone shell materials used in stringed instrument inlay, reverse glass signage, furniture, marquetry, jewelry, and a wide variety of other crafts.